Division 2 Rules Save $ On Nozzle Design

Did you know you can design safer and save money using ASME Division 2 rules instead of Division 1?

There are many ways to take advantage of the higher allowables and more accurate numerical methods in Division 2. One such method to consider is using the Bildy Rules instead of Area of Replacement for nozzle design.

Take a look at this simple nozzle internal pressure case:

Design Pressure = 290 psi (2000 kPa)

Design Temperature = 475°F (246°C)

Nozzle Material = SA-106 C Smls Pipe

Nozzle Size = NPS 12 Sch 140

The Division 1 vessel does not pass the design condition of 290 psi (2000 kPa) @475°F (246°C).

The Division 2 vessel passes the design condition of 290 psi (2000 kPa) @475°F (246°C).

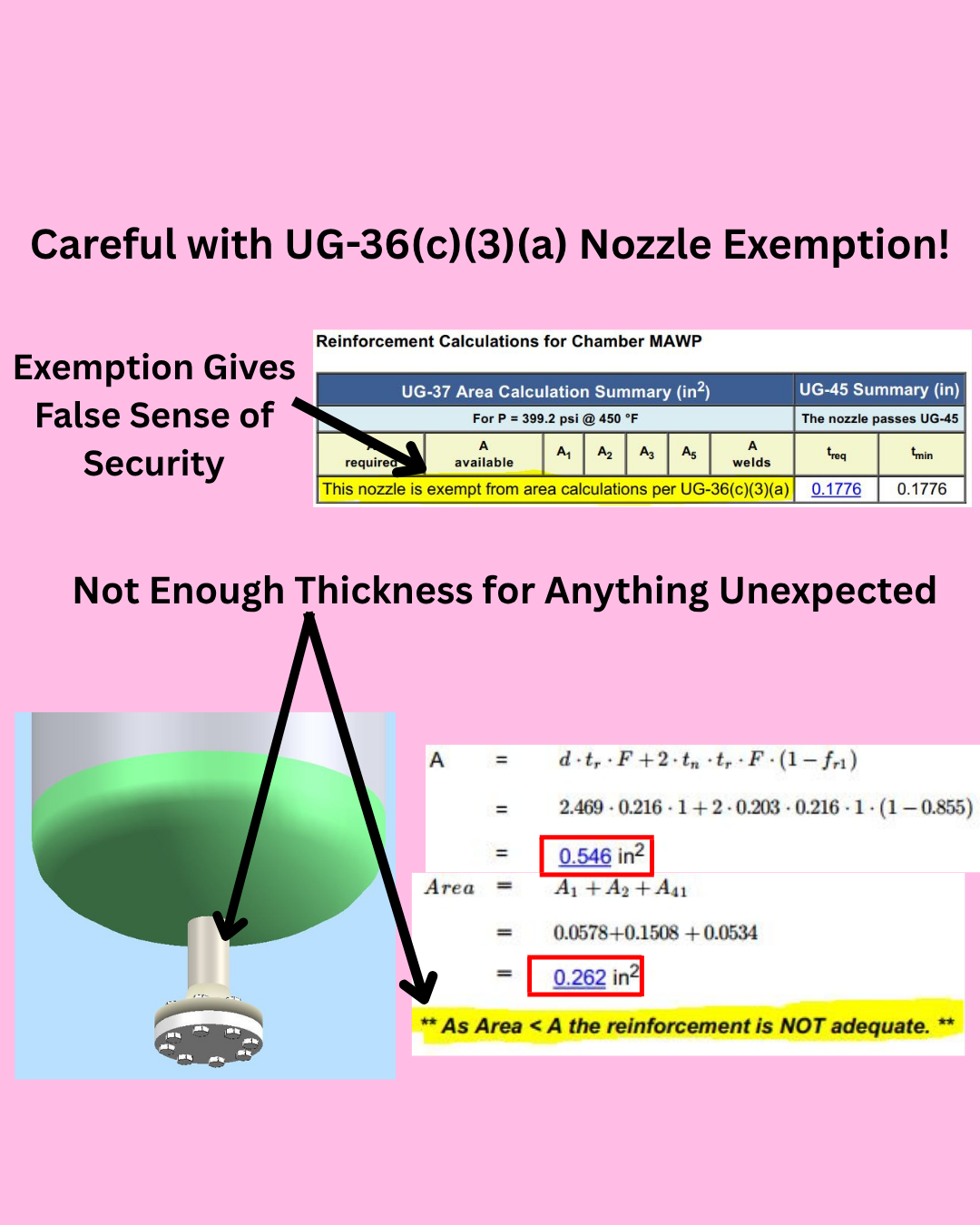

Do Not Use Calculation Exemptions on Important Process Nozzles

Do you use calculation exemptions on important process nozzles?

Yes, we all know nozzles under a certain size are exempted from the Division 1 nozzle area-of-replacement rules. That does not mean that you should use this exemption every time you can. Think very carefully about what each nozzle is used for and what the consequences of failure may be.

You may want to double-check exempted nozzles against another set of nozzle rules before finalizing your design. Are you around 90% of area-of-replacement? Fine. Are you around 50% of area-of-replacement like my example? You may want to add a little thickness to the nozzle. This is a bad place to try to save money on your design.

What if local corrosion is higher than the design corrosion?

There is no nozzle thickness to compensate for corrosion. Through wall corrosion is common.

What if nozzle loadings are higher than anticipated?

There is no extra thickness to handle pressure plus unexpected loadings.

What if an upset condition increases the process velocity?

There is no extra thickness to handle process erosion.

LWN Forged Flanges Required Nozzle Calculations

Are you performing the required calculations for your LWN forged flanges?

LWN forged flanges are popular among Owner/Operators because the ASME Codes offer some calculation exemptions. However some Owner/Operators have started to believe that LWN forged flanges are exempt from all calculations. This is a dangerous trend as LWN forged flanges are not automatically acceptable at their designated ASME B16.5 flange pressure rating classification. Yes, LWN forged flanges do have some similar exemptions as ASME B16.5 flanges but a full nozzle calculation must still be performed at the nozzle-to-vessel intersection.

Integrally Reinforced Nozzles

While visiting a client I was pleasantly surprised to see several tanks constructed with integrally reinforced nozzles. Everyone knows that I like to avoid designing with nozzle pads whenever possible. Integrally reinforced nozzles give the additional reinforcement necessary to resist membrane stress at the nozzle intersection without the negative repercussions of using nozzle pads.

In the past I had to use spreadsheets to manipulate the nozzle calculations to account for integral reinforcement. Now I can easily model these nozzles with the “Insert (Q) Lip” option in COMPRESS.

Notice that I don’t give up much stress resistance by using a 12” integrally reinforced nozzle over a 12” nozzle with nozzle pad.

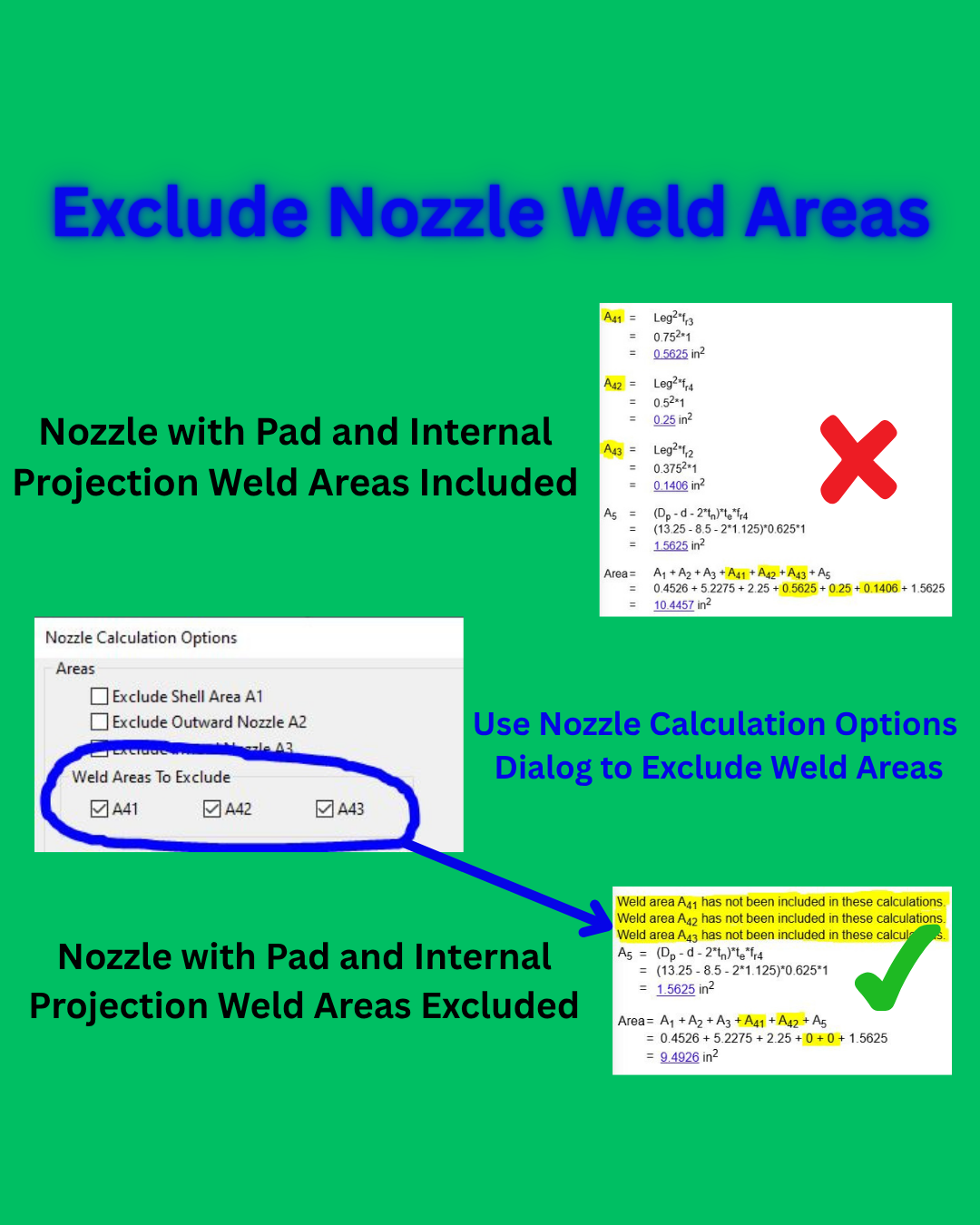

Excluding Weld Areas in UG-37 Calculation

Does your specification sheet require that nozzle weld areas not be included in your UG-37 area of reinforcement calculations?

No problem!

Nozzle and nozzle pad weld areas are easy to remove inside of the Nozzle Calculation Options dialog in COMPRESS. Notice each weld area can be controlled individually, giving maximum flexibility in the calculations.

As we all know, the ASME Code allows weld areas to be included in the area available for reinforcement. However, not all Owner/Operators allow these weld areas to be included in the area available for reinforcement calculations for their equipment. Remove these weld area calculations in COMPRESS without resorting to spreadsheets. Please refer to UG-37 for more information regarding nozzle reinforcement requirements.