Replace Traditional Half-Pipe Jackets with Omega Jackets

Reduced Pitch

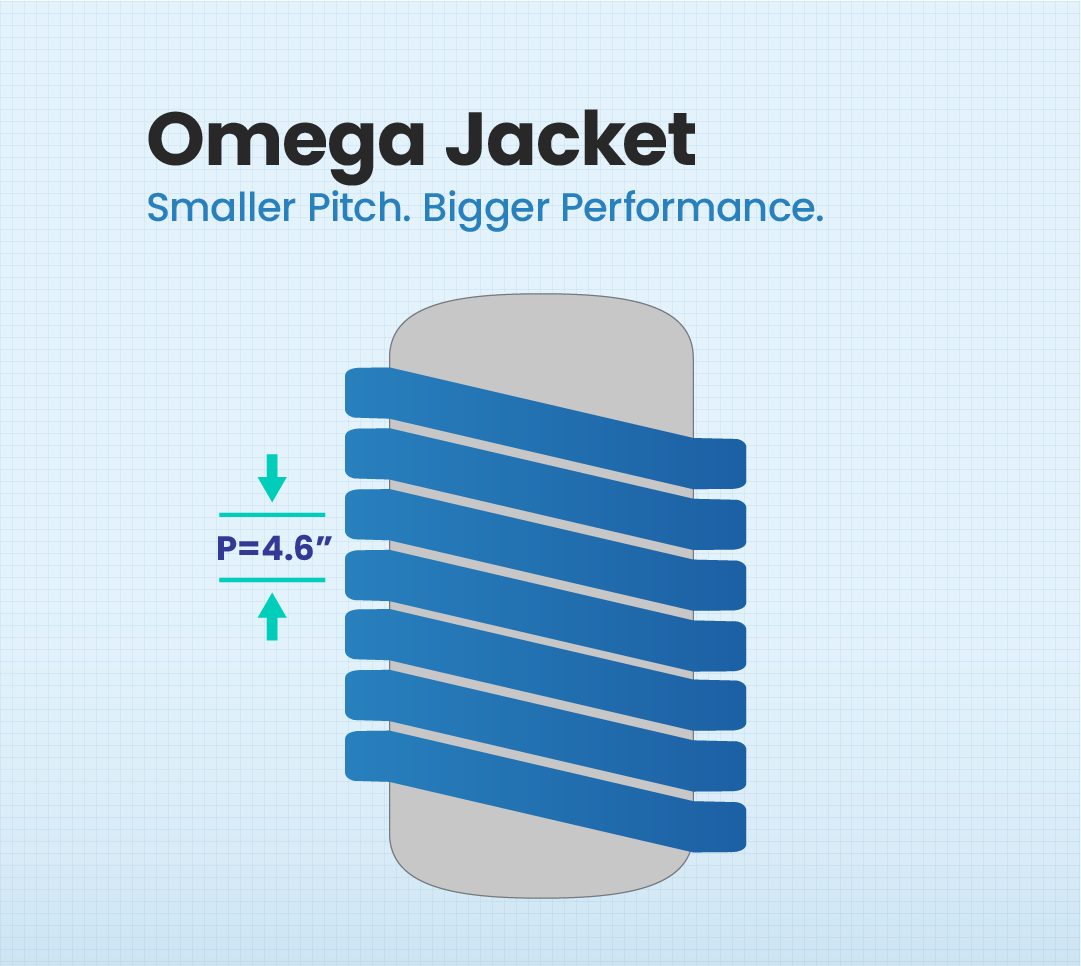

Reducing the pitch is a great way to improve the performance of half-pipe jackets. The welding methods used in traditional half-pipe jackets require a large pitch to accommodate spacing requirements. The butt welds in the Omega Jacket used in the Boltzmann Reactor allow for a reduced pitch, significantly increasing the performance.

Increased Area

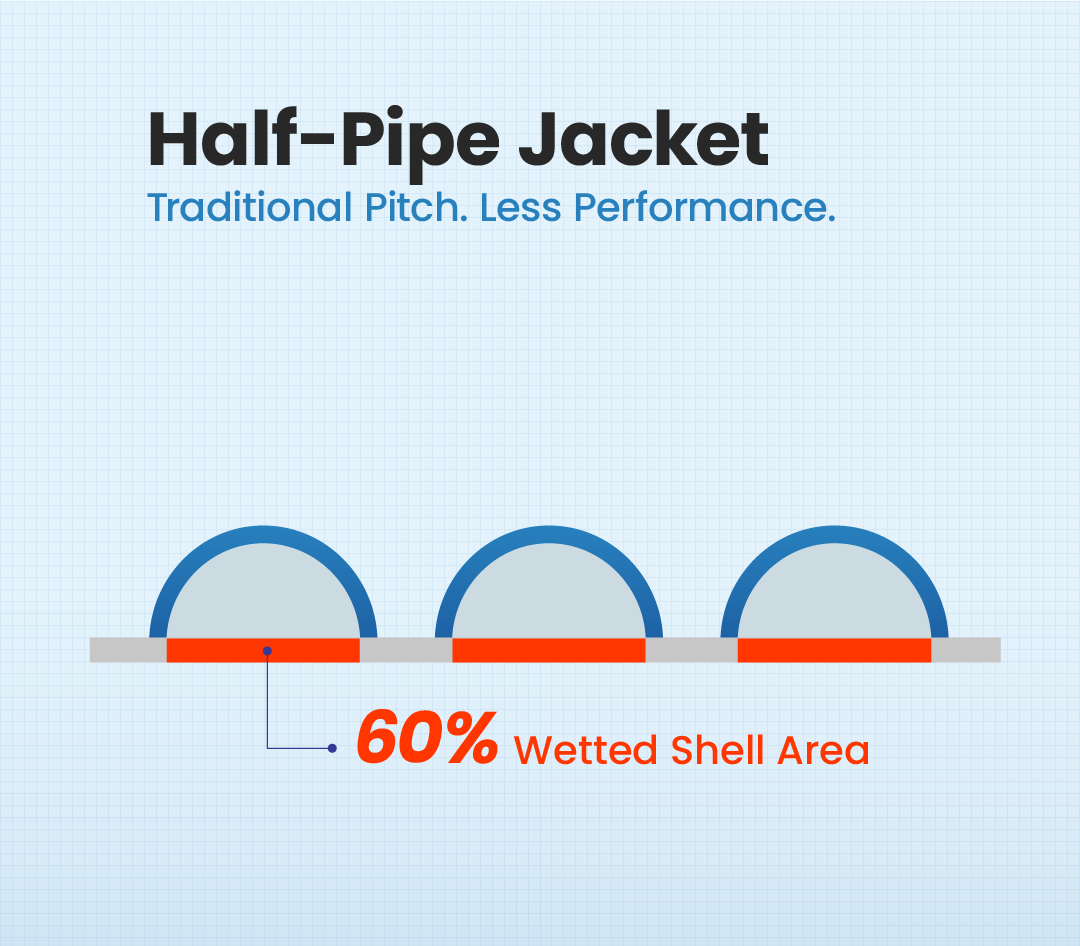

The larger wetted shell area of the Omega Jacket increases heat transfer rates by up to 30% compared to traditional half-pipe jackets.

Are you still replacing your old equipment in-kind instead of considering a new design that incorporates the latest design rules and manufacturing techniques?

LATTICEPT introduced one such example to me with the Omega Jacket, the half-pipe jacket featured in the Boltzmann Reactor. Notice how much better the Omega Jacket design is from traditional half-pipe jacket designs by connecting the coils with a single, inspectable butt weld.

Consider some advantages:

1) Less total welding means faster lead times.

2) The innovative geometry creates a smaller pitch and larger wetted shell area. This combination means better heat transfer than traditional half-pipe jackets.

3) Reduced welding complexity means lower cost.

4) Coils are butt welded instead of using fillet welds. Butt welds allow for much easier inspection.

5) Higher quality design greatly improves lifespan.