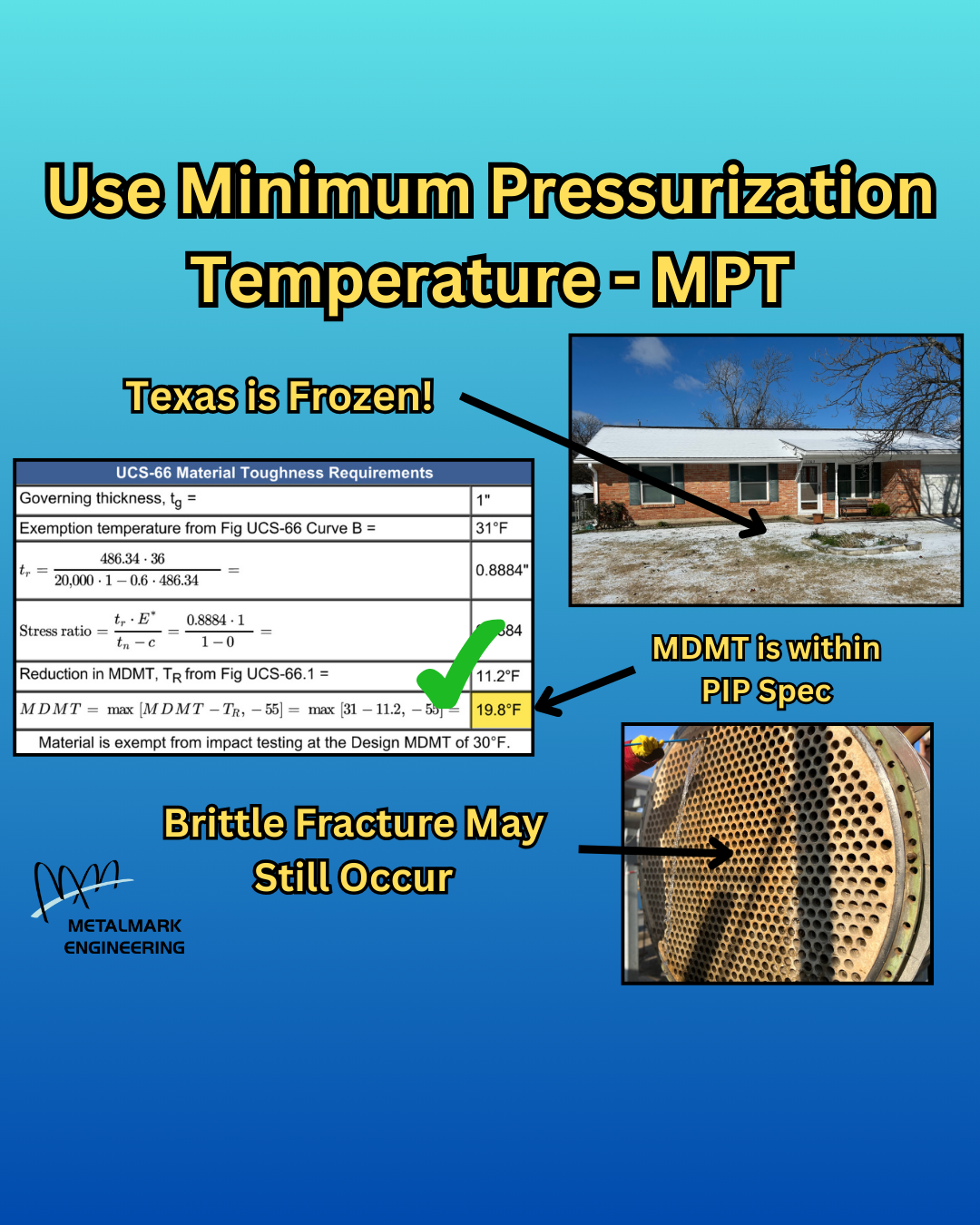

Use Minimum Pressurization Temperature (MPT)

Did you shut down during the ice storm? If so please check the Minimum Pressurization Temperature (MPT) before starting your equipment back up!

This is especially true for heat exchangers with thick carbon steel tubesheets.

I’ve seen many carbon steel tubesheets crack after ice storms. The tubesheets did not fracture during the storm itself. The tubesheets experienced brittle fracture when the heat exchanger was pressurized before warming up to an appropriate Minimum Pressurization Temperature MPT.

We all want to go fast but please be careful when restarting equipment after an ice event. Does your facility need help in determining MPTs? Turnaround EPC specializes in considering brittle fracture scenarios for your entire facility. Don’t let a cold weather event turn into an unplanned shutdown!

Consider Longitudinal Stresses in Brittle Fracture Check

Do you consider longitudinal stresses when you check for brittle fracture?

I’ve had a lot of people asking me to check their hydrotest temperatures. A design where a governing longitudinal stress case was not considered in the Minimum Design Metal Temperature (MDMT) stood out to me.

Did you know that longitudinal stresses can govern the MDMT even if circumferential stresses govern the Maximum Allowable Working Pressure (MAWP)? Not checking the longitudinal stresses can lead to devastating results as the brittle mode of failure is swift and catastrophic. Always remember to consider longitudinal stresses in your brittle fracture check.

Check Water Temperature Before Hydrotest

Please check the water temperature before performing your hydrotest. It may be too cold!

Have you ever seen a pressure vessel or heat exchanger crack due to brittle fracture during hydrostatic testing? Thousands of hours spent on calculations, drawings, welds, and inspections down the drain. Then the root cause investigation results in more time and money lost.

Brittle fracture can occur during hydrostatic testing when the water temperature used in the hydrotest is too close to the Minimum Design Metal Temperature (MDMT) of the material. This means that your equipment can pass the design MDMT calculations and still experience brittle fracture during hydrostatic testing. This simple temperature check is often missed and can lead to devastating results.

Please review UG-99 for more information regarding hydrostatic testing.

High Tube Bundle Replacement MDMT

A Minimum Design Metal Temperature (MDMT) of 100°F (38°C) for a brand new heat exchanger tube bundle installation?

How is this even possible?

I see these in service all the time when an Owner/Operator does not pay attention to the MDMT when replacing carbon steel tube bundles in heat exchangers with an original construction date prior to 1987. The MDMT calculation was not performed on these old tube bundles as they predate the MDMT calculation in the ASME Code.

Many times older exchangers have thick tubesheets constructed with UCS-66 Curve A materials that result in high MDMTs. Pressure-containing equipment with high MDMTs carry a high operational risk as the brittle fracture mode of failure is immediate and catastrophic. Please review the use of UCS-66 Curve A materials in your process. I prefer to upgrade material selection to a UCS-66 Curve C or Curve D material at the next scheduled tube bundle replacement.