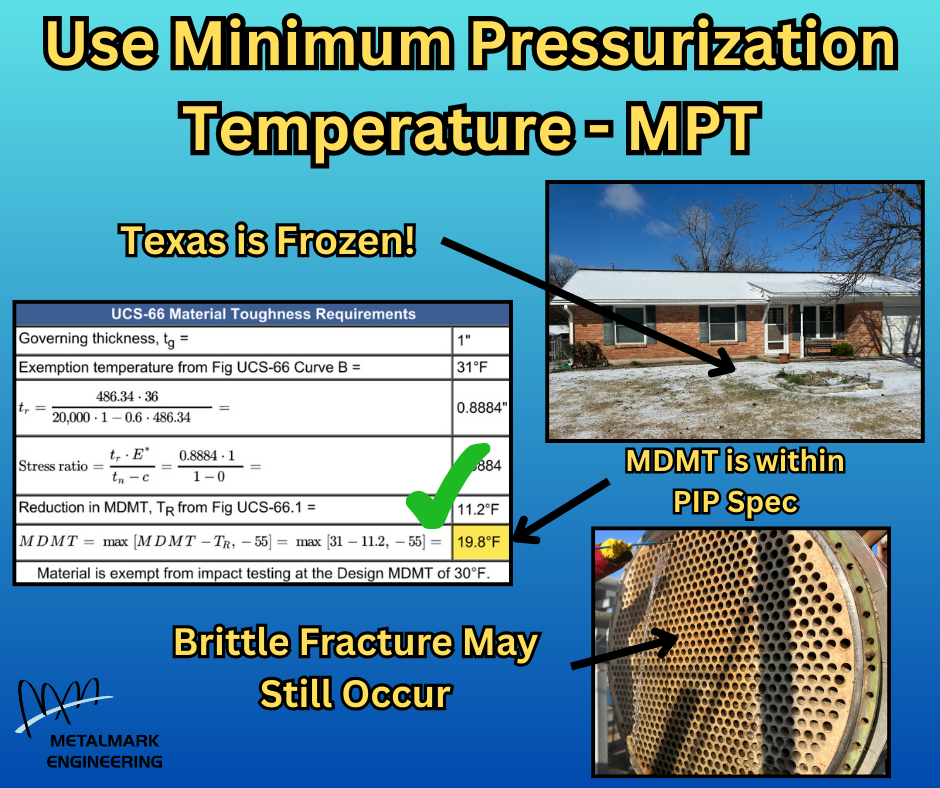

Use Minimum Pressurization Temperature (MPT)

Did you shut down during the ice storm? If so please check the Minimum Pressurization Temperature (MPT) before starting your equipment back up!

This is especially true for heat exchangers with thick carbon steel tubesheets.

I’ve seen many carbon steel tubesheets crack after ice storms. The tubesheets did not fracture during the storm itself. The tubesheets experienced brittle fracture when the heat exchanger was pressurized before warming up to an appropriate Minimum Pressurization Temperature MPT.

We all want to go fast but please be careful when restarting equipment after an ice event. Does your facility need help in determining MPTs? Turnaround EPC specializes in considering brittle fracture scenarios for your entire facility. Don’t let a cold weather event turn into an unplanned shutdown!