Calculate B16.9 Elbows by Outer Diameter (OD)

Like to use ASME B16.9 Elbows as main pressure containing components? Please remember to treat them as seamless pipe and to calculate the required thickness by outer diameter. This means using Appendix 1-1 instead of UG-27 for internal pressure in Division 1.

I see off-the-shelf ASME standard flanges and pipe fittings often used as main pressure containing components in pressure vessels and heat exchangers. I’ve noticed the biggest variance in approach when I investigate ASME B16.9 Elbow calculations. Some design engineers believe that ASME B16.9 Elbows do not require any calculations at all. Others calculate ASME B16.9 elbows using UG-27. Very few use Appendix 1-1.

Notice that Appendix 1-1 may require extra thickness compared to UG-27. Please refer to UG-44 for more information regarding the calculation of standard flanges and pipe fittings.

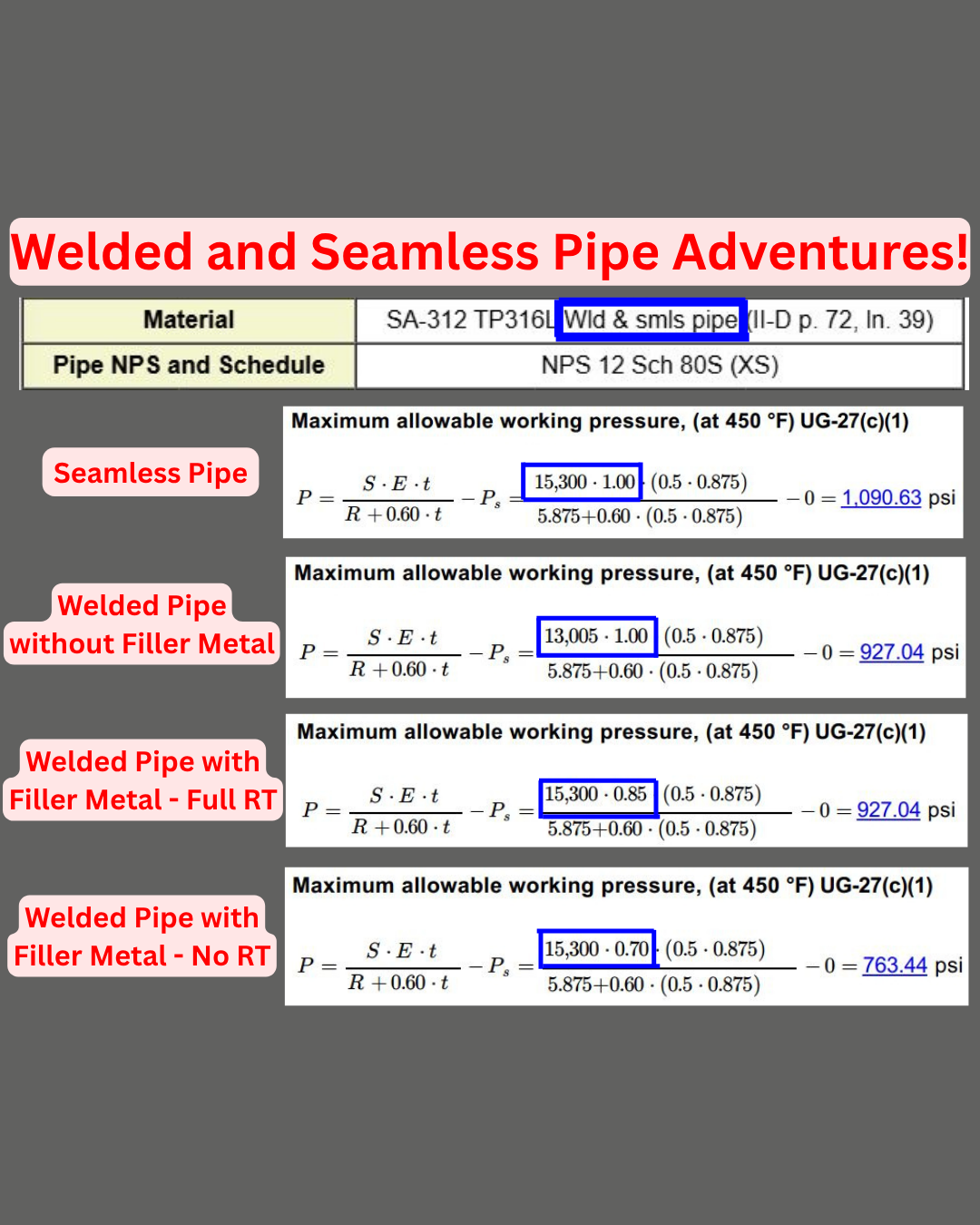

“Welded and Seamless Pipe” Product Form

Let’s talk about my favorite product form “Welded and Seamless Pipe”.

Is it Welded? Is it Seamless? Is it Both? Wait, that’s impossible…

Well then what is a “Welded and Seamless Pipe”? I have no idea. What I do know is that there is a big difference between how welded pipe and seamless pipe are handled when it comes to ASME Code calculations. You need to know exactly which version of the material you have before performing calculations or there is a good chance you will be making a big mistake.

Let’s take a look at SA-312 TP316L, which includes the seamless and welded pipe product form in the same specification.

Seamless: No need for a longitudinal weld joint efficiency factor in the allowable stress. Double-check to make sure the allowable stress reflects this.

Welded Pipe Made without Filler: The longitudinal weld joint efficiency factor needs to be included in the allowable. Notice the allowable is (15,300 x 0.85 = 13,005). There is no need to count this twice and multiply by 0.85 again in the joint efficiency value.

Welded Pipe Made with Filler: The joint efficiency factor was not included in the allowable so it needs to be taken into consideration in the joint efficiency value itself. Keep in mind that the joint efficiency value may be lower than 0.85 depending on the radiography performed.

Do You Need to Multiply Welded Pipe Allowables by 0.85?

Do you need to multiply welded pipe material allowables by 0.85?

I get a lot of questions regarding the allowable stresses for various material product forms. The one I’ve been asked about a lot recently is whether or not the allowable stress for welded pipe needs to be multiplied by 0.85.

The answer is, probably not, but it depends. You really need to take a look at the material notes for your welded pipe material in ASME Section II, Part D. This will reveal whether or not the lookup allowable in ASME Section II, Part D has already been multiplied by 0.85. Let’s take a look at a couple of the notes in Table 1A:

G24: This note indicates that the 0.85 has already been applied to the allowable stress. You do not need to multiply the allowable stress by 0.85 again. In this example the allowable stress lookup of 14,600 psi can be used directly in circumferential stress equations.

W12: This note indicates that the 0.85 has not been applied to the allowable stress. You need to multiply the allowable stress by 0.85 if the welded pipe was created without using filler metal. In this example the lookup of 21,400 psi was multiplied by 0.85 to achieve the 18,190 psi allowable used in the circumferential stress equations.

The ASME Section II, Part D material notes are not just informational, they can directly affect the allowables you used in stress equations.