Maximum Permissible Bolt Stress, Sbmax

Let’s talk about the Maximum Permissible Bolt Stress, Sbmax needed for the PCC-1 Appendix O calculation.

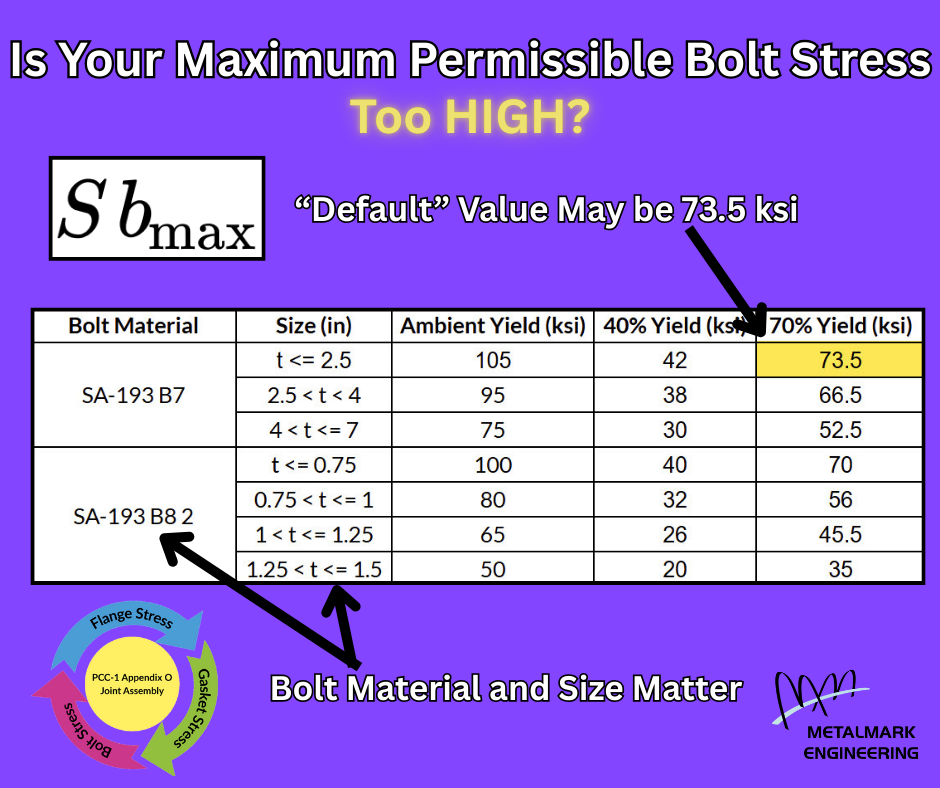

When performing 3rd party PCC-1 Appendix O reviews I often see a “default” value of 73.5 ksi (507 MPa) used for all bolt sizes and all bolt materials. Understand that 73.5 ksi (507 MPa) represents 70% Yield of SA-193 B7 bolts under 2.5”. Please remember to look up the yield stress to determine Maximum Permissible Bolt Stress, Sbmax values for other materials and sizes above this range as this value may be TOO HIGH for your application.

Let’s take a look at what the Maximum Permissible Bolt Stress, Sbmax, depends on.

Material:

Notice that SA-193 B8 2 stainless steel bolts above 1.25” have less than half of the ambient yield of SA-193 B7 bolts. Choosing the wrong material’s yield stress can have a big impact on your PCC-1 Appendix O results.

Size:

Notice that the bolt size has a big influence on ambient yield stress and the yield stress may be drastically lower at larger sizes. Also notice that the size ranges given for ambient yield stresses vary by material. Looking up the ambient yield stress at the wrong size can be a determining factor on the quality of your PCC-1 Appendix O results.

Maximum Permissible Bolt Stress, Sbmax

Bolts seem like the simplest part of the PCC-1 Appendix O calculation but they are often a source of bad assumptions. Unsure about your PCC-1 Appendix O results? Metalmark Engineering loves checking your PCC-1 Appendix O calculations to determine the source of leaky gaskets.