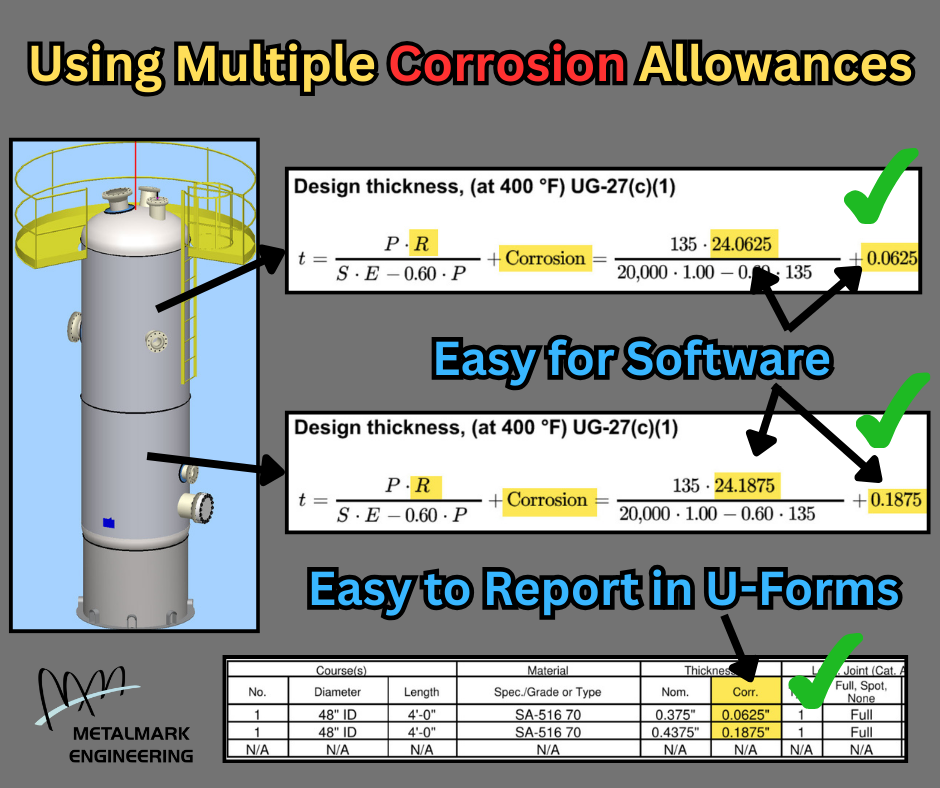

Using Multiple Corrosion Allowances

Don’t be afraid to use two different corrosion allowances in your static equipment design. It’s no big deal!

Many processes create two (or more) streams with different corrosion rates. Assigning the same corrosion allowance for each of these stream sections in your equipment may not make sense.

The designers bidding on your new static equipment have fancy software that easily handles multiple corrosion allowances. This means calculating equipment required thicknesses using multiple corrosion allowances adds 𝐧𝐨𝐭𝐡𝐢𝐧𝐠 to the engineering design cost. U-forms clearly report multiple corrosion allowances for each shell section so adding multiple corrosion allowances to U-Forms is not a problem either. Mechanical integrity programs will split the equipment sections into the appropriate corrosion loops anyway. In fact, your mechanical integrity program will 𝐠𝐫𝐞𝐚𝐭𝐥𝐲 𝐚𝐩𝐩𝐫𝐞𝐜𝐢𝐚𝐭𝐞 assigning the appropriate corrosion allowance to sections that have higher corrosion rates.

I have found that many times mechanical integrity departments are forced to live with bad decisions made with the initial equipment design. Inspecting the same equipment over-and-over again is much more expensive than designing the equipment correctly in the first place. Metalmark Engineering is not afraid to use multiple corrosion allowances in their designs; you shouldn’t be afraid either.