Division 2/Appendix 46 Assessments

Why use Metalmark Engineering for your Division 2 assessment?

Speed in Proving Viability: We quickly determine if your pressure vessel or heat exchanger is a good candidate to use Division 2 rules*.

Calculation Accuracy: We are experienced in using the latest software tools to generate Division 2 ASME Code calculations.

Cost Savings: Due to the differences in the Division 1 and Division 2 Code computations, designs using Division 1 Code calculations may require additional material than designs using Division 2 Code calculations. Taking advantage of these differences may result in significant cost savings.

Lead Time: Pressure vessels and heat exchangers designed using Division 2 rules may require significantly fewer welds; designs with fewer welds can significantly reduce your lead time.

Process Experience: We are experienced in identifying API 571 damage mechanisms in process equipment and piping. From material selection to long-term maintenance plans, we are experienced in supporting the integrity of your process equipment.

Division 2 Rules for Heavy Barrel Nozzles

Using heavy barrel nozzles? Then it may be a great time to consider using the Division 2 rules for your vessel design.

The large shell section removed makes heavy barrel nozzles tough to pass Division 1 Area-of-Replacement rules. Part of the issue is because too much of the heavy barrel ends up outside of the limits of reinforcement. A frustrating result for designers expecting a big advantage from the extra nozzle thickness!

The Division 2 nozzle rules use the Bildy method instead of Area-of-Replacement. This method calculates the nozzle stresses in a completely different manner, which is advantageous for heavy barrel nozzle design. Notice that the exact same nozzle easily passes at the exact same design pressure and temperature.

With the new 2025 ASME Code changes there has never been a better time to begin learning and using the Division 2 rules. Not sure where to start? Let Metalmark Engineering help your understanding of the differences between the Division 1 and Division 2 rules.

Division 2 Rules are Safer and Save Money

Did you know you can design safer and save money using ASME Division 2 rules instead of Division 1?

There are many ways to take advantage of the higher allowables and more accurate numerical methods in Division 2. One such method to consider is using the Bildy Rules instead of Area of Replacement for nozzle design.

Take a look at this simple nozzle internal pressure case:

Design Pressure = 290 psi (2000 kPa)

Design Temperature = 475°F (246°C)

Nozzle Material = SA-106 C Smls Pipe

Nozzle Size = NPS 12 Sch 140

The Division 1 vessel does not pass the design condition of 290 psi (2000 kPa) @475°F (246°C).

The Division 2 vessel passes the design condition of 290 psi (2000 kPa) @475°F (246°C).

I recommend against designing with nozzle reinforcing pads whenever possible. This is one simple example where a nozzle reinforcing pad is avoided by using Division 2.

Use Division 2 Nozzle Rules with Appendix 46

Are you using the Division 2 nozzle rules yet?

I know a lot of Owner/Operators are afraid of using the Division 2 rules because they are weary of using higher allowable stresses. Did you know that you can apply the lower Division 1 allowables with the Division 2 rules by using Appendix 46 in Division 1 designs? This means engineers like me can still save big money where the Division 2 rules offer a clear advantage. This is especially evident in nozzle design where the Bildy rules often avoid extraneous nozzle reinforcement compared to the Division 1 area-of-replacement rules.

Using Appendix 46 for External Pressure

Have you started using the Appendix 46 solution for external pressure calculations?

I encourage you to become familiar with the Appendix 46 external pressure solution as the more accurate calculation method provides benefits over the Division 1 solution. Try creating a spreadsheet for the Appendix 46 external pressure method and compare it to the Division 1 solution over a wide range of diameters and materials. This helped build my confidence in the method and will build your confidence too.

Take a look at this simple 8’ inner diameter carbon steel vessel at 425°F where the Appendix 46 solution passes the vacuum case and the Division 1 solution fails the vacuum case.

Save Money using ASME Division 2 Rules

Can you save money using ASME Division 2 rules instead of Division 1?

There are many ways to take advantage of the higher allowables and more accurate numerical methods in Division 2.

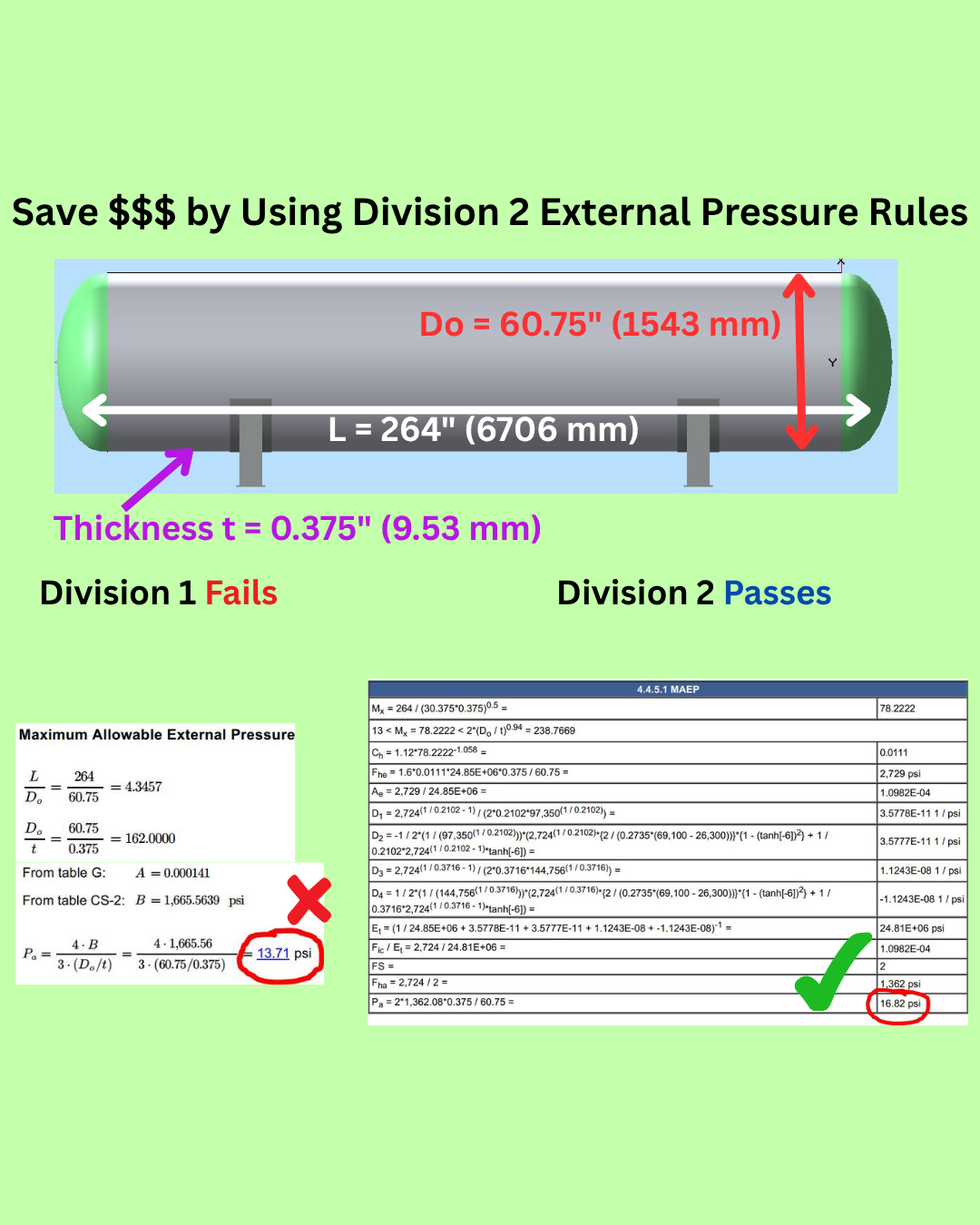

Take a look at this simple external pressure (vacuum) case:

Outside Diameter, Do = 60.75” (1543 mm)

Thickness, t = 0.375” (9.53 mm)

Unsupported Length, L = 264” (6706 mm)

The Division 1 vessel does not pass the vacuum condition of 14.7 psi (101 kPa).

The Division 2 vessel passes the vacuum condition of 14.7 psi (101 kPa).