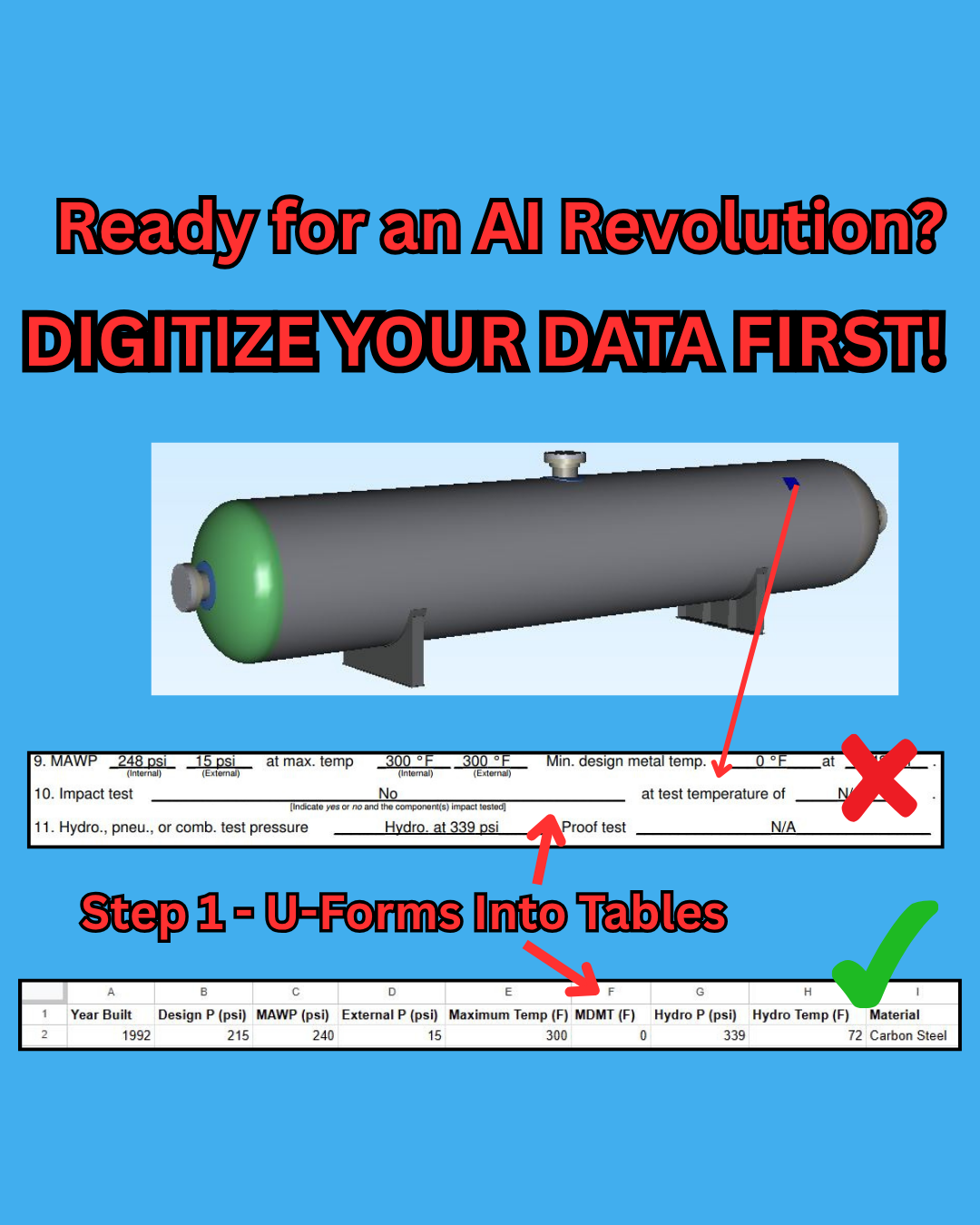

Move Data from U-Forms into Spreadsheets for AI

Are you ready for AI? Your data is not.

One of the big themes of Reuters Downstream 2025 was the use of AI in maintenance and inspection. I found the concept of using AI for predictive analytics in maintenance incredibly intriguing. However, let’s not pretend that your important data is in a format that AI can actually use. You need to digitize your data.

Are your U-Forms sitting in a filing cabinet somewhere?

How about the historical measured thickness data from internal inspections? Are those values just floating around in PDFs?

What about the interesting information found during external inspections? Repairs? Rerates? Derates? FFS assessments? Wouldn’t you want all of that data digitized in a way that makes it easy for AI to pull from?

We all know that AI is the future but AI is only as good as the data you are feeding it. Consider yourself behind if the items listed above are not in a usable, digital format.

Towers Falling During Postweld Heat Treatment (PWHT)

Have you seen a tower fall during Post Weld Heat Treatment (PWHT)?

As crazy as it sounds I’ve seen this occur when PWHT is applied around the circumferential seams of tall towers in the field. The solution is often even crazier as Owner/Operators prefer expensive materials analysis and complex FEA calculations over simple explanations. The fact is the tower behaved exactly as expected as it was never designed to take such loadings at temperature.

So what is actually happening?

1 - The Wind case was not properly considered by the design engineer

2 - The Wind case in the Empty condition was not calculated

3 - The much lower allowable stress in the material at temperature was not considered

4 - Wind loads during PWHT create a large moment that the material was not designed to resist

5 - DOWN IT GOES!!!

Calculate B16.9 Elbows by Outer Diameter (OD)

Like to use ASME B16.9 Elbows as main pressure containing components? Please remember to treat them as seamless pipe and to calculate the required thickness by outer diameter. This means using Appendix 1-1 instead of UG-27 for internal pressure in Division 1.

I see off-the-shelf ASME standard flanges and pipe fittings often used as main pressure containing components in pressure vessels and heat exchangers. I’ve noticed the biggest variance in approach when I investigate ASME B16.9 Elbow calculations. Some design engineers believe that ASME B16.9 Elbows do not require any calculations at all. Others calculate ASME B16.9 elbows using UG-27. Very few use Appendix 1-1.

Notice that Appendix 1-1 may require extra thickness compared to UG-27. Please refer to UG-44 for more information regarding the calculation of standard flanges and pipe fittings.

Be Careful with RT-4 Vessels in Corrosive Service

I think it’s time we talk about “RT 4” vessels and heat exchangers. I see them everywhere in corrosive processes and highly consequential service and I really wish I didn’t.

So what is “RT 4”? Well “RT 4” simply means that “RT 1”, “RT 2”, or “RT 3” do not apply. It does not mean anything else specifically about what kind of weld inspection was applied to the vessel.

How much radiography or other weld inspection is applied to a vessel marked “RT 4”? Some? None? I don’t know, but probably not a lot. I personally assume that no weld inspection was performed unless proven otherwise. This is where I have a problem with “RT 4” vessels and exchangers. I don’t feel comfortable placing vessels and heat exchangers in service without having some sort of assurance regarding the quality of the welds. When I uncover the root cause of unplanned shutdowns too many times these “RT 4” vessels are to blame.

I consider the cost of maintenance and inspection in my designs and I do not believe any money is saved in the long run by operating “RT 4” vessels.

LWN Forged Flanges Required Nozzle Calculations

Are you performing the required calculations for your LWN forged flanges?

LWN forged flanges are popular among Owner/Operators because the ASME Codes offer some calculation exemptions. However some Owner/Operators have started to believe that LWN forged flanges are exempt from all calculations. This is a dangerous trend as LWN forged flanges are not automatically acceptable at their designated ASME B16.5 flange pressure rating classification. Yes, LWN forged flanges do have some similar exemptions as ASME B16.5 flanges but a full nozzle calculation must still be performed at the nozzle-to-vessel intersection.

Do You Need to Multiply Welded Pipe Allowables by 0.85?

Do you need to multiply welded pipe material allowables by 0.85?

I get a lot of questions regarding the allowable stresses for various material product forms. The one I’ve been asked about a lot recently is whether or not the allowable stress for welded pipe needs to be multiplied by 0.85.

The answer is, probably not, but it depends. You really need to take a look at the material notes for your welded pipe material in ASME Section II, Part D. This will reveal whether or not the lookup allowable in ASME Section II, Part D has already been multiplied by 0.85. Let’s take a look at a couple of the notes in Table 1A:

G24: This note indicates that the 0.85 has already been applied to the allowable stress. You do not need to multiply the allowable stress by 0.85 again. In this example the allowable stress lookup of 14,600 psi can be used directly in circumferential stress equations.

W12: This note indicates that the 0.85 has not been applied to the allowable stress. You need to multiply the allowable stress by 0.85 if the welded pipe was created without using filler metal. In this example the lookup of 21,400 psi was multiplied by 0.85 to achieve the 18,190 psi allowable used in the circumferential stress equations.

The ASME Section II, Part D material notes are not just informational, they can directly affect the allowables you used in stress equations.