Expensive Hydrotests

Sometimes performing the ASME Code required hydrotest is deemed too expensive so Owner/Operators skip it.

One factor that may raise the cost of hydrotesting is if the hydrotest pressure is much greater than the operating pressure. The higher hydrotest pressure may require the fabrication of single-use components, supplying a special set of gaskets, and another PCC-1 Appendix O calculation.

One of the sad realities of the extreme cost-cutting associated with modern manufacturing is the loss of basic design principles. I’ve noticed that performing proof tests and leak tests instead of ASME Code required hydrotests is becoming increasingly popular in new vessel construction.

Authorized Inspectors (AIs) often assume a shop hydrotest was performed and never check the U-Form notes that clearly states otherwise. The “what can I get away with?” mentality rewards design engineers with promotions while operator roles become increasingly dangerous.

ASME PCC-1 Appendix O

ASME PCC-1 Appendix O has a lot of stress values to look up (or calculate) and using “defaults” isn’t going to help you solve real world problems. Over the next few weeks I’ll be going over where to get some of the stress values you will need in order to properly determine bolt torque values using ASME PCC-1 Appendix O.

Maximum Permissible Bolt Stress, Sbmax

Minimum Permissible Bolt Stress, Sbmin

Target Assembly Gasket Stress, SgT

Maximum Permissible Gasket Stress, Sgmax

Minimum Operating Gasket Stress, Sgmin-O

Minimum Seating Gasket Stress, Sgmin-S

Assembly Bolt Stress, Sbsel

Wait, just seven stress values? That seems way too easy! It is! But let’s start here and save the Maximum Permissible Bolt Stress for the Flange, Sfmax determination calculation using WRC 538 for after your exam.

Use ASME PCC-1 Appendix O to Fix Leaky Gaskets

Do you have an issue with leaky gaskets?

A lot of people message me complaining about leaky flange gaskets and wondering what kind of gaskets I recommend to help. The fact of the matter is that gasket quality and performance has never been better. I have found that many times the real problem is that the gasket was not considered during the design phase. Gaskets are an important part of flange design. Treat them that way.

Have you performed ASME PCC-1 Appendix O for your flanges?

An approach in ASME PCC-1 Appendix O can help you make sure your gaskets are being seated correctly. The gasket needs to be below the maximum permissible gasket stress, above the minimum seating gasket stress, and above the minimum gasket operating stress. In this example the minimum gasket operating stress is not being maintained at the operating condition.

Make sure you perform ASME PCC-1 next time you open up a pair of flanges.

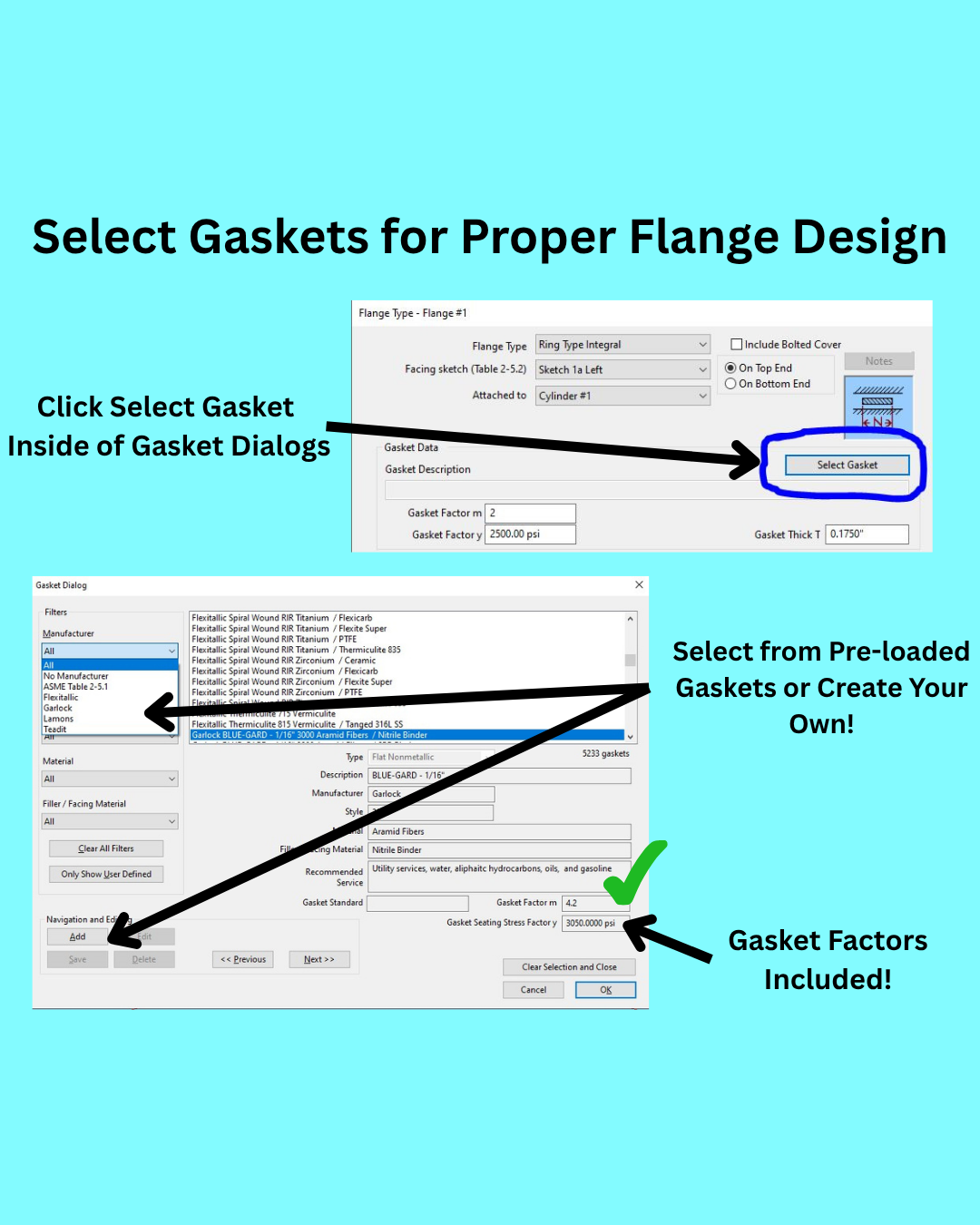

Simple Gasket Look-Up in COMPRESS

Do you spend too much time looking up Gasket Factor (m) and Gasket Seating Stress Factor (y) values?

Whenever someone asks me to design a custom Appendix 2 or Part 4.16 flange I want to know the m and y factors of the gaskets they intend to use. A lot of times this crucial gasket design information is tough to track down. Thankfully COMPRESS has a great selection of pre-loaded gaskets to choose from including manufactures like Garlock, Flexitalic, Lamons, and Teadit.

Use a manufacturer not listed in COMPRESS? It is easy to add new gaskets to the pre-loaded database.